MILLING

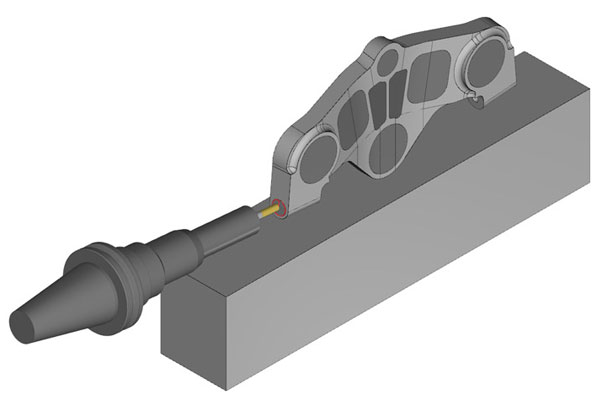

ESPRIT SolidMill® is a full-spectrum suite of milling cycles for facing, roughing, contouring and finishing, and hole making. With ESPRIT's Modeless Programming™, these cycles are universally available on any class of CNC machine: vertical, horizontal, and gantry mills, millturn, and lathes - including Swiss-type. With SolidMill cycles, quickly generate efficient milling toolpaths while keeping extensive control over the movements of the cutting tool, supporting unique requirements of individual parts. Automatic calculation of the stock allows the system to generate efficient toolpaths while avoiding tool breakage and collisions. Machine-optimized G-code uses the advanced functions of the CNC, such as helical and polar interpolation, high-speed and high-precision options, and the machine's built-in canned cycles.

In short, SolidMill:

- Is a full-spectrum suite of milling cycles universally available for any class of CNC machine.

- Quickly generates toolpath with extensive control to support the unique requirements of each part.

- Produces edit-free, machine-optimized G-code

Model-Driven Machining

Programming Automation

Holemaking

Facing & Roughing

Contouring & Finishing

Optimized for Remaining Stock

Profit Milling

This high-speed machining cycle is designed for roughing to significantly reduce cycle times and increase tool life. Its patented technology automatically manages chip loads and lateral cutting forces, while also maintaining the cutter engagement angle and machine axes acceleration within ideal ranges. With ProfitMilling, the machine can take deeper cuts at increased feedrates which are also automatically tuned throughout the toolpath for optimal results. Compared to traditional machining, ProfitMilling delivers:

- 75% reduction of cycle time

- 500% increase in tool life

SolidMill Cycles

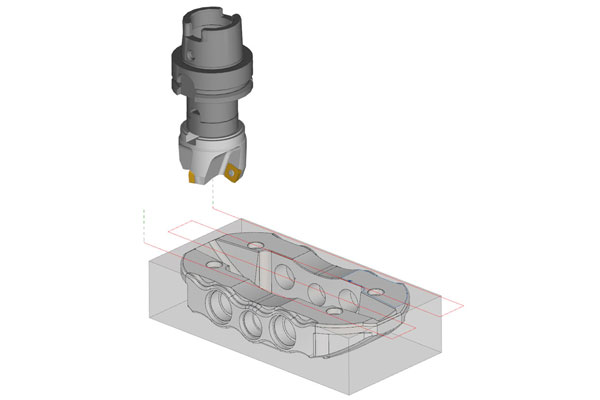

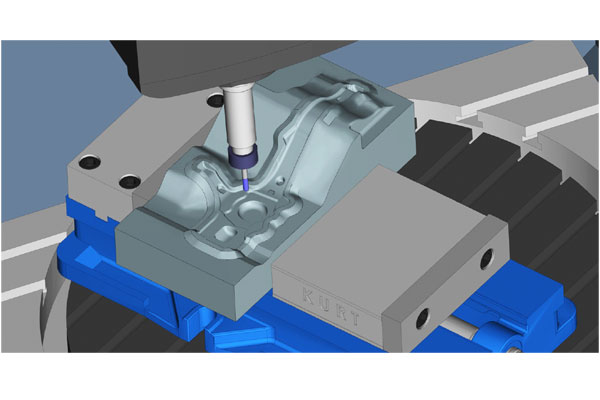

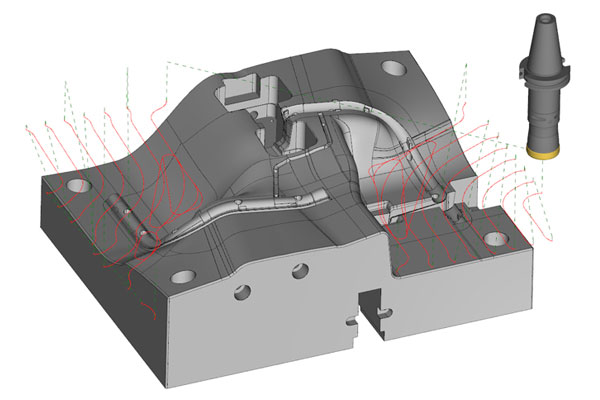

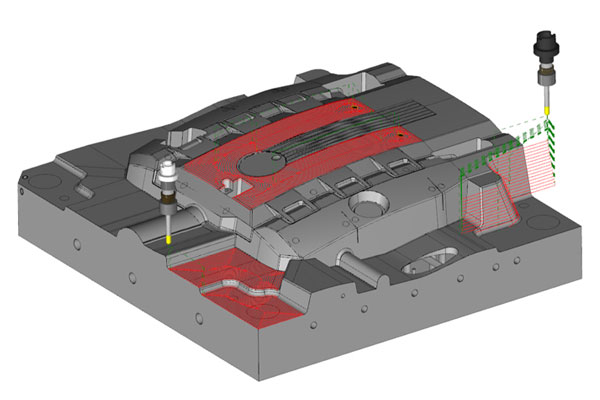

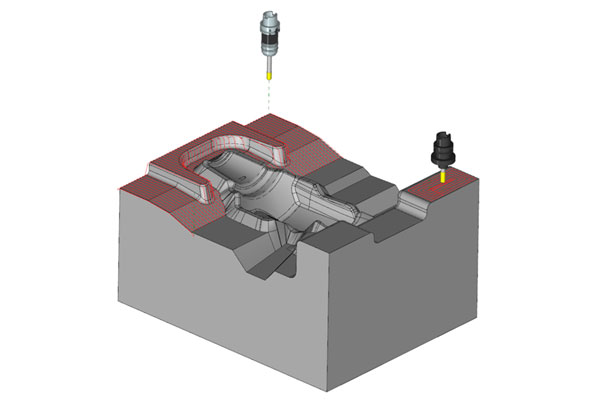

3-AXIS MILLING

ESPRIT offers a powerful suite of 3-axis machining cycles for roughing, prefinishing, finishing, and remachining of complex freeform parts. ESPRIT SolidMill FreeForm™ is extensively used by customers in mold and die, tool making, discrete parts, and model-making markets. Each of ESPRIT's 3-axis machining cycles are optimized for machining 3D models that may include surfaces, solids, and STL geometry. With ESPRIT's Modeless Programming™, the FreeForm cycles may be used on any configuration of mill, lathe, mill-turn, and Swiss-type machine. These 3-axis cycles may also be combined within any other ESPRIT cycle to create one complete part program for the entire part.

- A powerful suite of 3-axis cycles for machining complex freeform parts, used by customers in mold and die, tool making, discrete parts, and model-making markets

High-Performance Roughing

Prefinishing

Finishing

Remachining

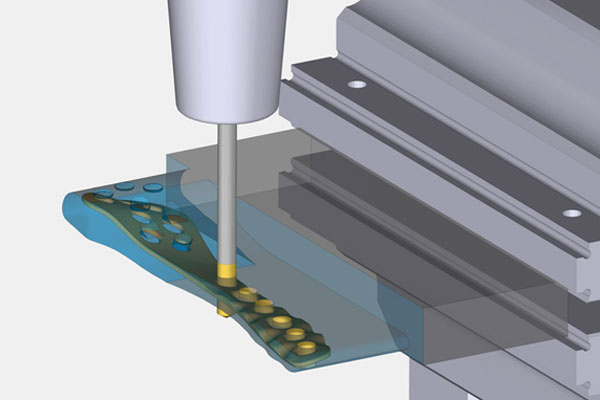

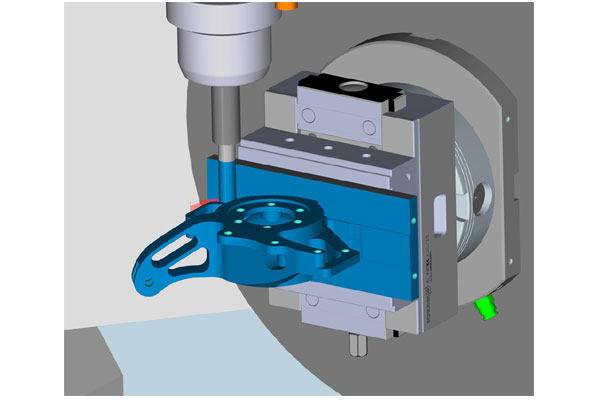

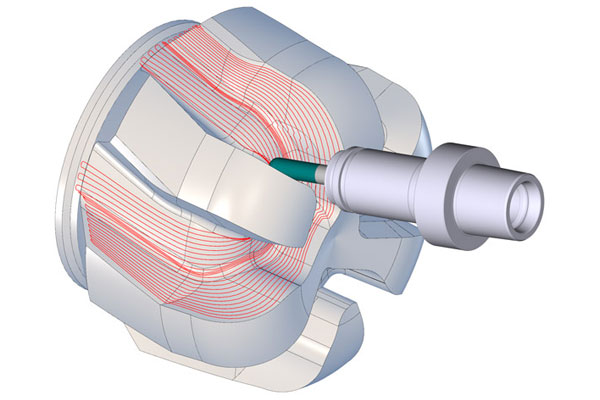

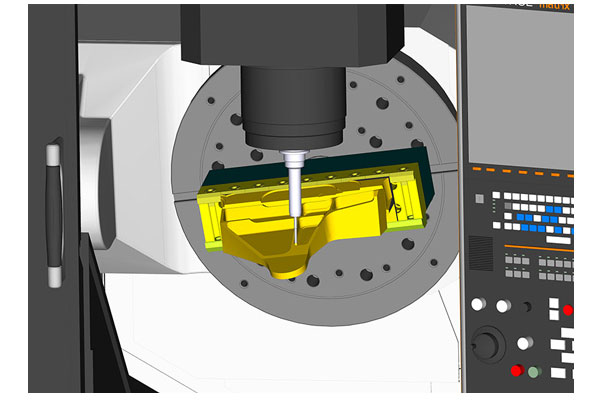

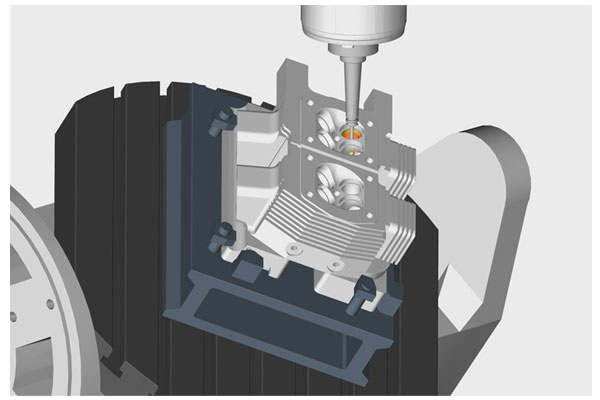

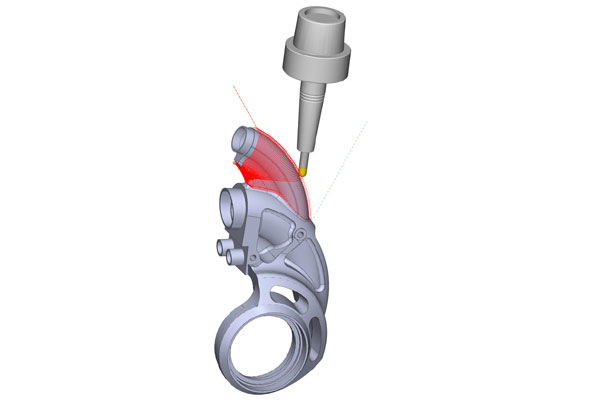

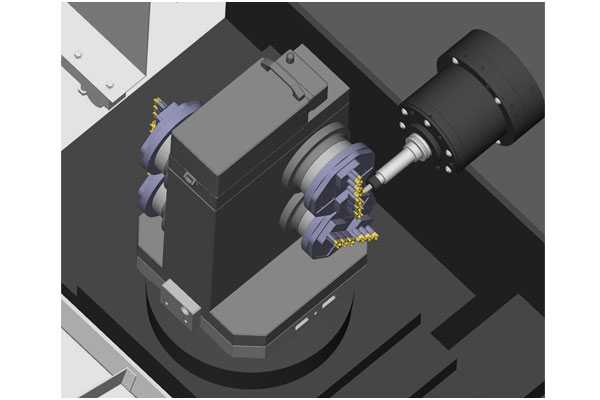

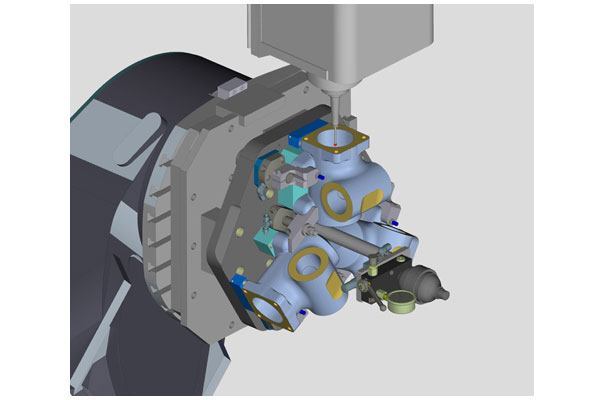

5-AXIS MILLING

ESPRIT offers FreeForm simultaneous 5-axis machining cycles that deliver machine-optimized toolpaths for 5-axis, 4+1, and 3+2 applications to produce complex tools and parts for a variety of industries, including aerospace, automotive, energy, and medical. These Adaptive Machining™ cycles are optimized to run on any class of CNC capable of 5-axis, including mills, multitasking mill-turns, and Swiss-type machines. As a full-spectrum CAM system, ESPRIT's 5-axis cycles can be combined with other milling, turning, and inspection cycles to create one complete part program that supports the needs of all machining and on-machine inspection.

- Machine-optimized 5-axis, 4+1, and 3+2 toolpaths to machine complex freeform shapes.

- Machine-optimized 5-axis, 4+1, and 3+2 toolpaths to machine complex freeform shapes.

- Adaptive Machining™ cycles that run on any class of CNC milling machine and any other CNC capable of 5-axis, including multitasking mill-turns and Swiss-type machines.

- Combine FreeForm cycles with any other milling, turning, and inspection cycles into one complete program.

Simultaneous 5-Axis

Stock-Aware Toolpath

Machine-Optimized G-Code

Optimizing the Program

Full Machine Simulation

FreeForm 5-Axis Cycles

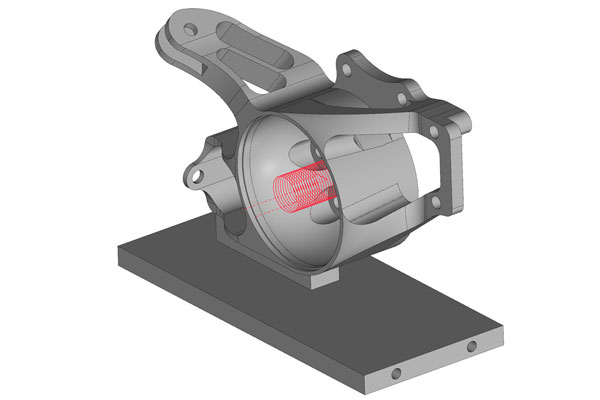

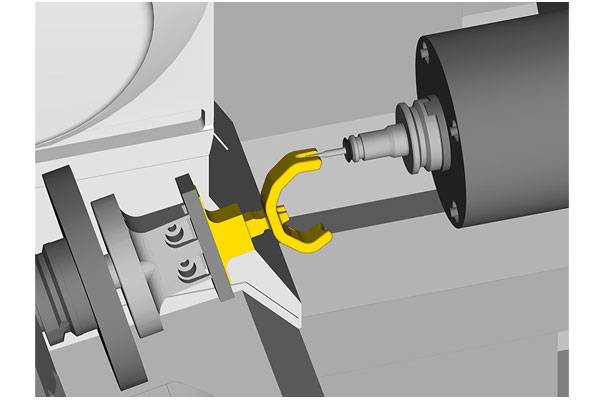

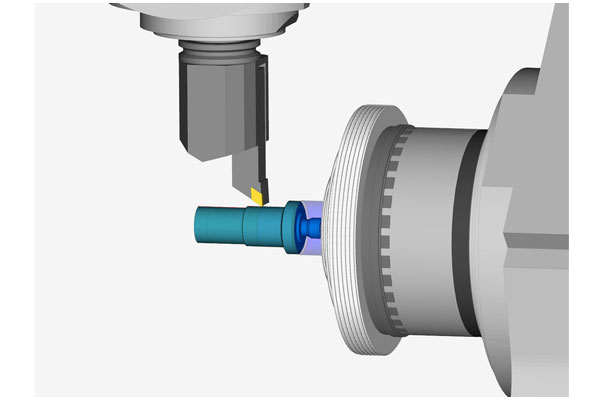

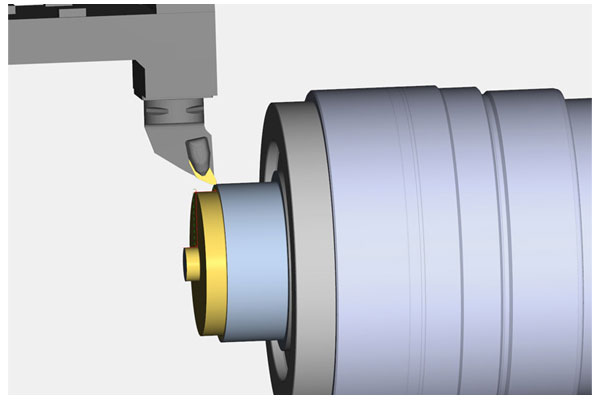

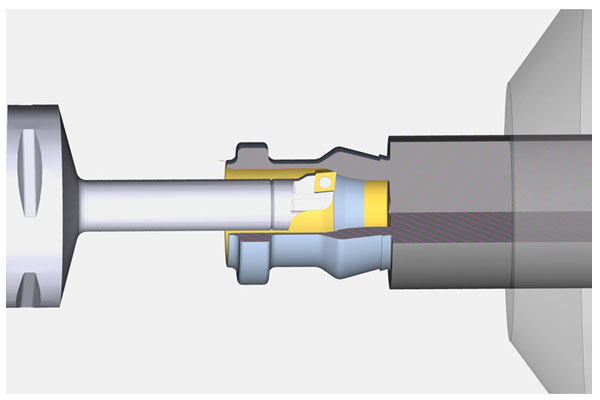

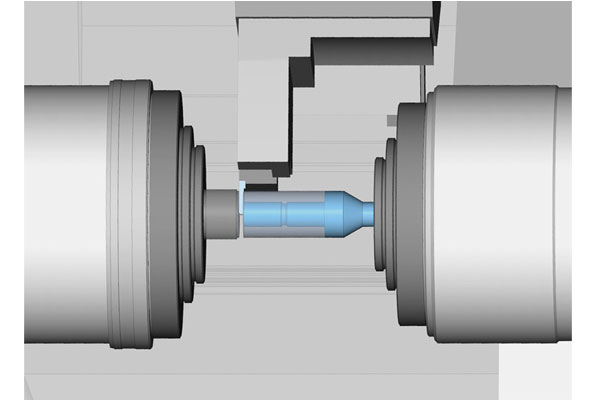

TURNING

SolidTurn® is a suite of turning and part handling cycles available for use on any class of CNC lathe, mill, or millturn machine. Use ESPRIT's Modeless Programming to combine turning cycles with any of ESPRIT's other machining and inspection cycles to create one complete process with machine-optimized, edit-free G-code. As a full-spectrum solution, SolidTurn quickly produces efficient rough and finish toolpaths for a wide variety of workpieces and machining situations. To support unique requirements for specific parts and materials, ESPRIT offers extensive user control of individual cutter movements. These stock-aware machining cycles consider the remaining stock, tool assembly, workholding, and the complete virtual machine to assure an optimized and collision-free toolpath.

- Turning and part handling cycles for use on any class of CNC lathe, mill, or millturn.

- Combines milling, turning, and probing cycles into one program.

- Quickly produces efficient toolpaths for a wide variety of workpieces and machining situations.

- Extensive toolpath control supports unique requirements for special parts and materials.

A Full-Spectrum Solution

Simplicity & Control

Roughing

Contour Turning

Grooving & Threading

Holemaking

Part Handling & Stock Support

SolidTurn Cycles

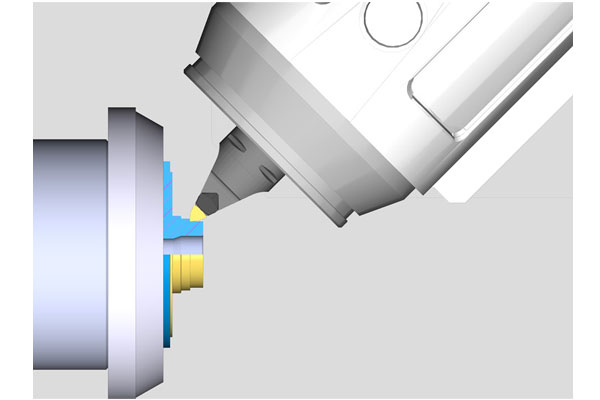

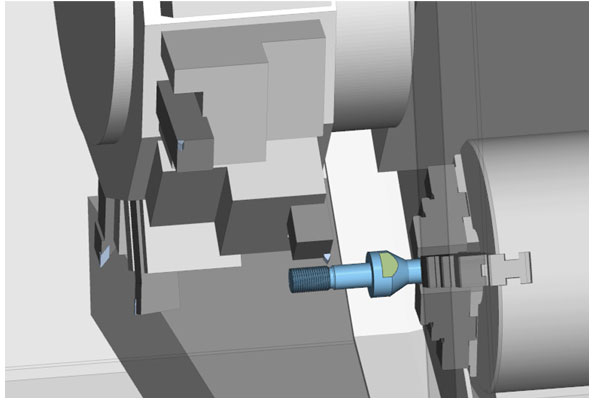

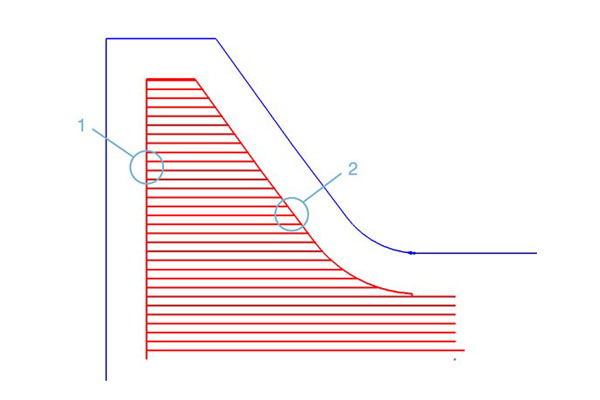

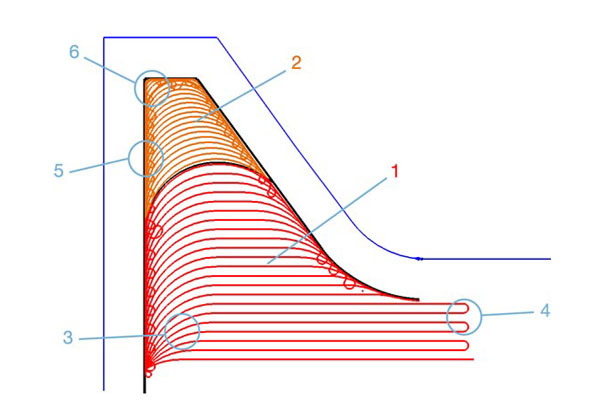

HIGH SPEED TURNING

High-speed rough turning with ProfitTurning, an innovative lathe roughing strategy that helps eliminate the adverse effects of traditional roughing and grooving cycles. ProfitTurning enables manufacturers to make more efficient cuts with consistent chip loads and cutting forces, thereby reducing tool wear, decreasing cycle times, and reducing cost per part up to 60%. This is achieved using an enhanced toolpath algorithm based on an engagement control strategy, which allows for consistent chip load and cutting forces universally and achieves the highest level of productivity.

- 300% increase in tool life.

- 25% cycle-time reduction.

Traditional Turning Method

Advantages of ProfitTurning

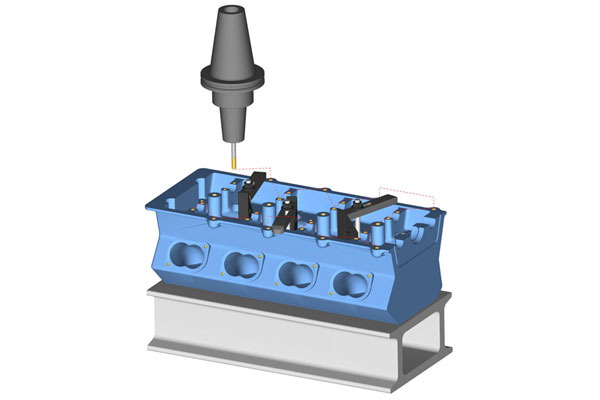

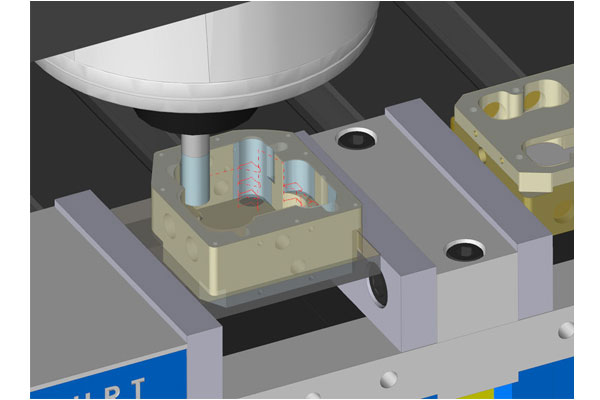

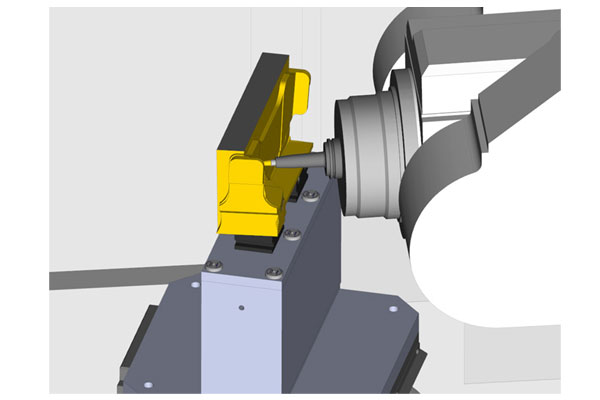

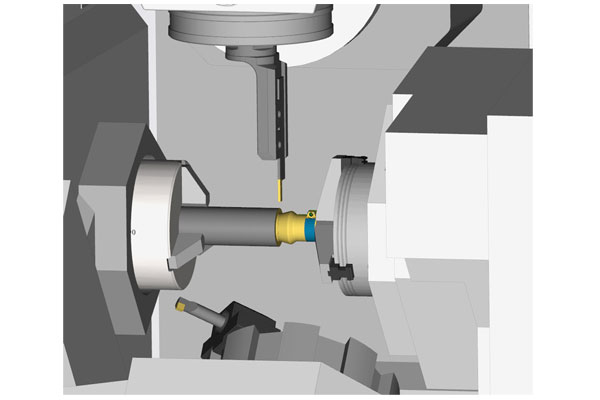

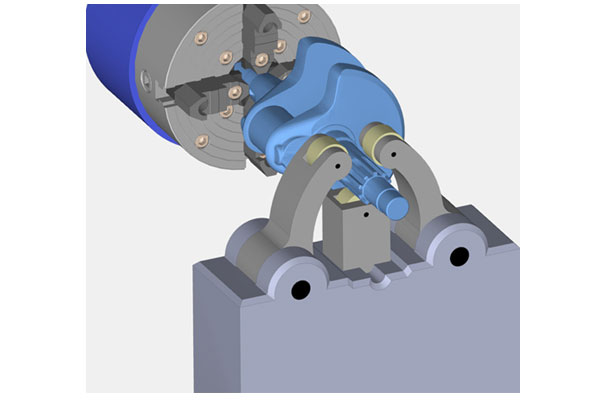

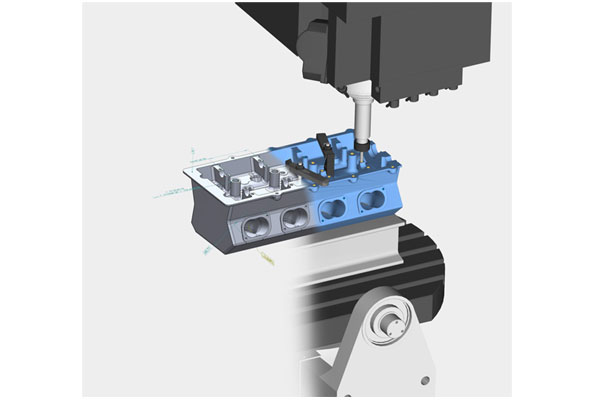

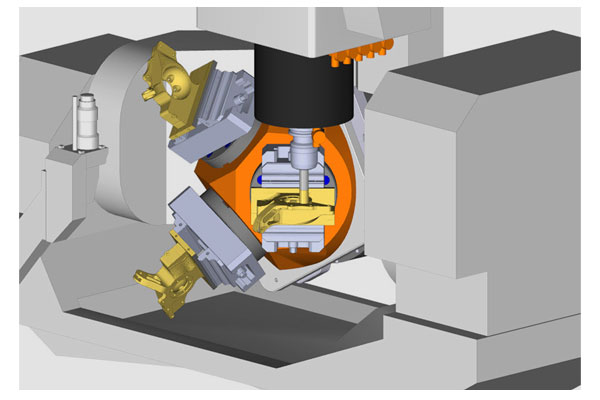

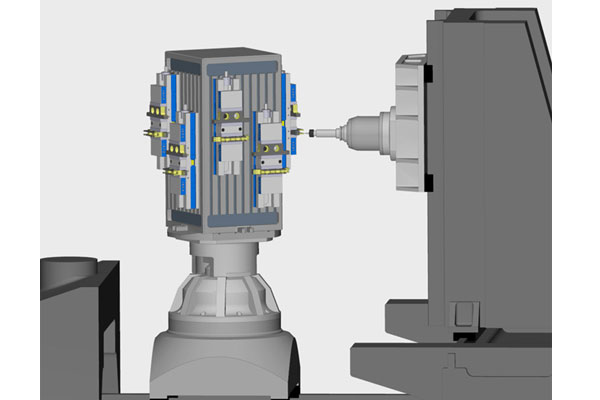

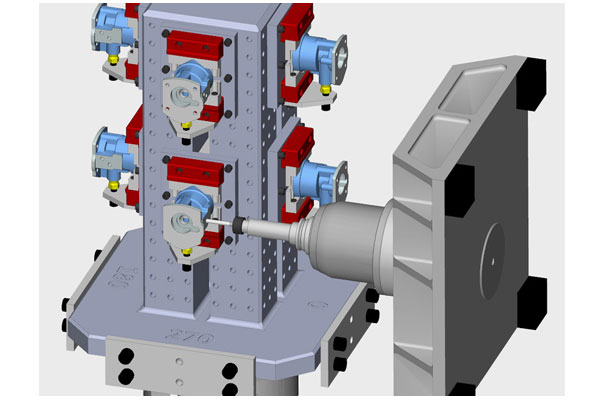

PRODUCTION MACHINING

ESPRIT delivers powerful programming, accurate simulation, and machine-optimized G-code for any class of CNC machine tool including horizontal, vertical, and gantry machines. As a full-spectrum solution for high value-added parts, processes, and demanding machining applications, ESPRIT is the right choice for any industrial application, from job shop work to large-scale heavy equipment manufacturing. With ESPRIT, production machining includes the ability to combine milling, turning, and probing cycles into one program to utilize the full capability of the machine tool and maximize shop productivity.

- Powerful programming, accurate simulation, and machine-optimized G-code for any class of CNC machine tool.

- Combining milling, turning, and probing cycles into one program.

- Utilizing the full capability of the machine tool and maximizing shop productivity.

A Natural Workflow

Program One Part, Machine Many

Programming with a Digital Twin

Optimized Production

Intelligent Work Offsets

Automatic Link Generator